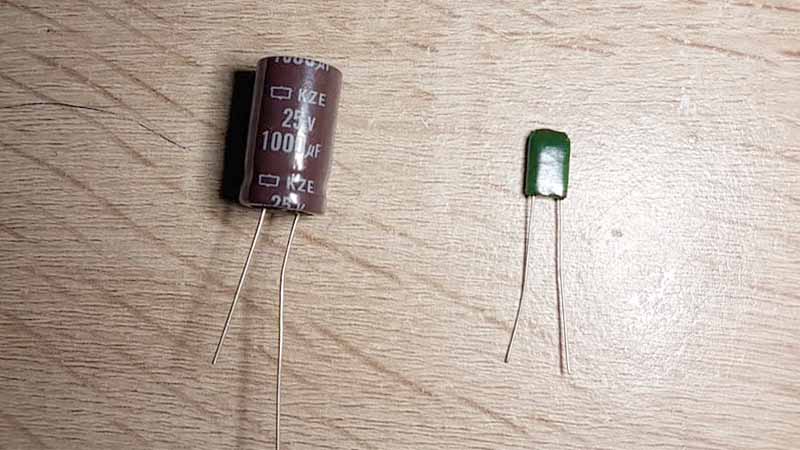

Electronic devices contain several different types of capacitor, such as film capacitors, paper capacitors, supercapacitors, electrolytic capacitors, and ceramic capacitors. The two types of capacitors that we will focus on in this article are electrolytic capacitors and capacitors.

Electrolytic Capacitors

Electrolytic capacitors use metal foil as their positive electrode and an oxide layer insulator as their dielectric. There are also other materials used, including electrolyte conductive materials and cathode materials.

You would use electrolytic capacitors in conjunction with medium frequency circuits or low-frequency circuits. Their job is to couple, decouple, and filter signals, as well as block direct currents. Even though electrolytic capacitors have a high capacity, they cannot withstand high voltage amounts. Not only that, but the capacity is not so stable either. That means the lifespan of electrolytic capacitors is not very long.

It is best to use electrolytic capacitors in low-frequency circuits and low-voltage circuits. Why? Their low-pass filters can block low-frequency ripples very well. Just make sure you don’t use electrolytic capacitors in AC power circuits.

Applications

Alternating current polarization and tight tolerances are unnecessary for many applications. But they do need huge capacitance values to function correctly.

A perfect example is filters that lower the voltage ripple of power supplies. If you put a high-quality capacitor in a power supply with a switch, it will let you limit the power supply with the switch. Another example is if you need to use it as a low pass filter to smooth the input and output whenever you have a DC signal and a defective AC component.

Electrolytic capacitors are not recommended for high-frequency signals and huge amplitude signals because of the power dissipation associated with the equivalent series resistance. You should use a capacitor with low equivalent series resistance in an application if you want to prevent overheating and losses.

Audio amplifiers are famous for having filters with electrolytic capacitors in them. The capacitors are there to decrease the mains hum. Without the capacitors, the mains supply would create an electrical noise that is between 50Hz and 60Hz. If the noise were to be amplified, people would be able to hear it.

Read also:

- Pros and Cons of Wind Power Turbines

- Top 5 Best Small Wind Power Turbines for Home Use

- Top 5 Best Capacitors for Audio Power Supply

- Top 5 Best Ultra/Super Capacitor (Battery less) Jump Starters

Ceramic Capacitors

Ceramic capacitors use a ceramic layer as their dielectric. The layer is positioned in the middle of two conductive plates.

The ceramic capacitors used the most are called multi-layer chip capacitors. They contain several conductive plates with a ceramic layer positioned in the middle of every two plates. They function as several small capacitors with parallel connections to produce one large capacitance.

Applications

The electronics industry produces more multi-layer chip capacitors than any other type of capacitor. Virtually every electronics application contains one or more of these capacitors. You can find these high-power capacitors in high-voltage power circuit breakers, laser power supplies, and induction furnaces.

Ultra-small surface mount capacitors are in high-density applications. Some of them are as small as a grain of sand. DC-DC converters use these capacitors, even though all the high electrical noises and frequencies puts wear and tear on the components.

Ceramic capacitors are unpolarized and found in many different capacitances, sizes, and voltage ratings. They are general-purpose capacitors that serve many purposes, especially for hobbyists and people in the robotics field.